The BMW M54 & S54 engines remain some of the most iconic inline-six powerplants in automotive history. Developed in the late 1990s and early 2000s, these engines solidified BMW’s reputation for engineering excellence, balancing performance, reliability, and tunability. As successors to the M52 and S50 engines, the M54 and S54 were crafted to elevate naturally aspirated engine performance for both daily driving and motorsport applications. Their engineering legacy continues to inspire modern BMW engine designs, including the later N52.

Source: BMW

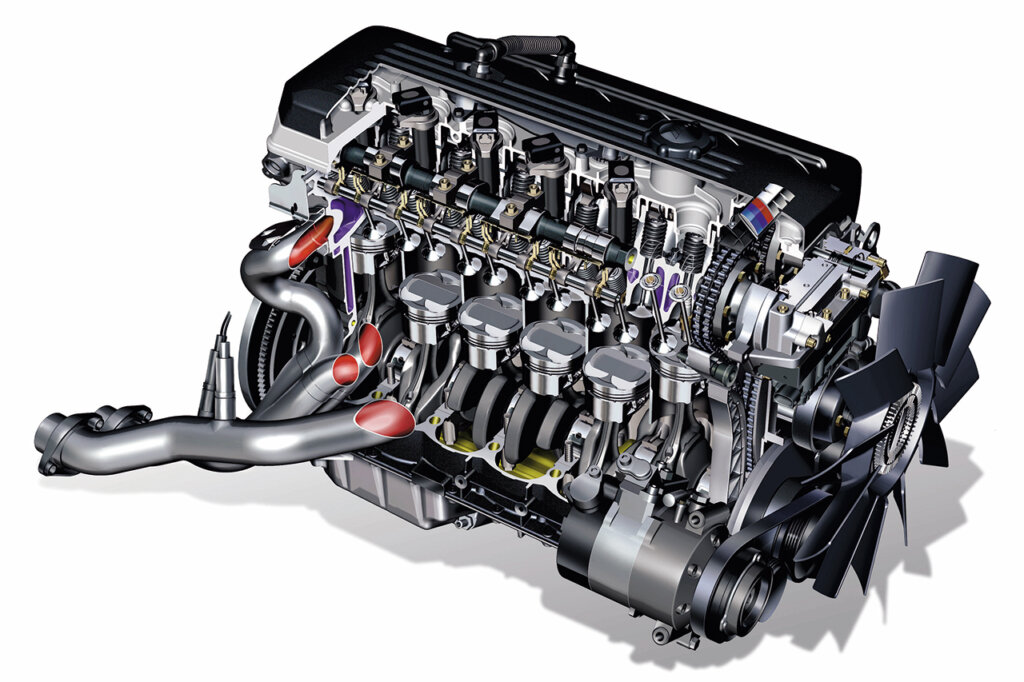

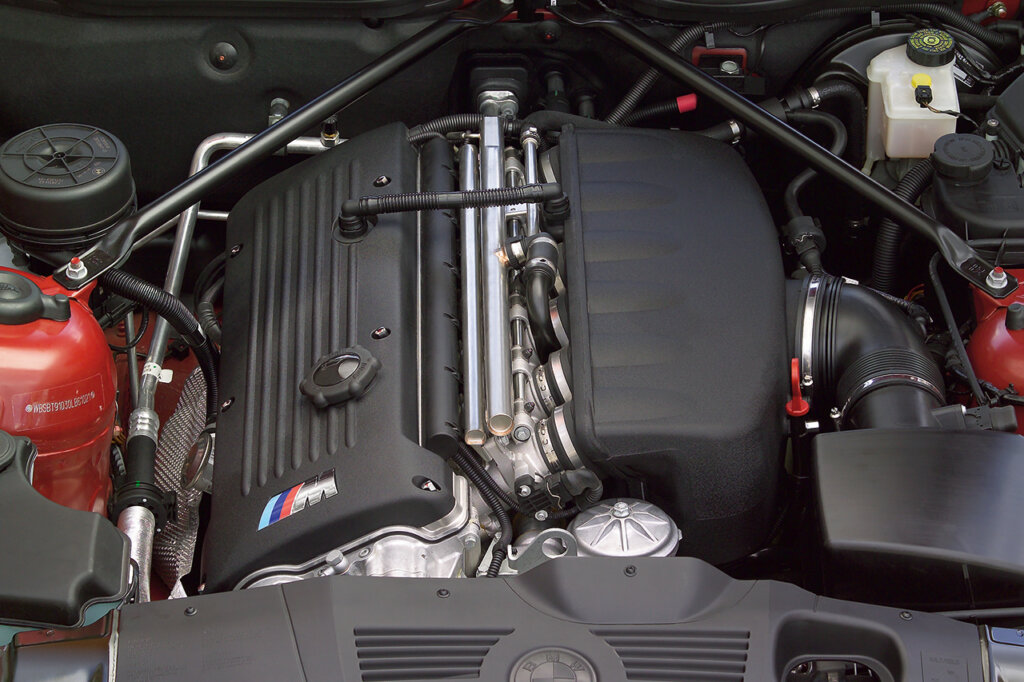

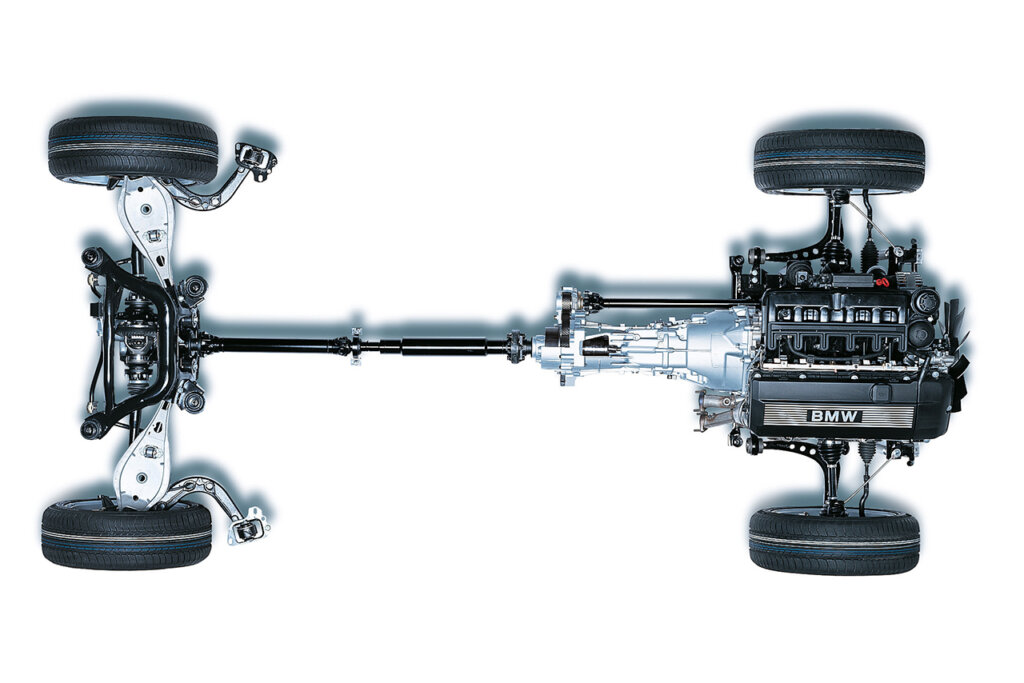

The M54 engine was introduced in 2000 as a naturally aspirated inline-six designed for a range of BMW models, including the E46 3-Series, E39 5-Series, and Z4 roadster. It utilized an aluminum block with cast iron cylinder liners, paired with an aluminum head, ensuring a lightweight yet robust construction. The inline-six configuration, synonymous with BMW’s engineering philosophy, offered smooth power delivery and exceptional balance. The M54B30, the largest variant, produced 228 horsepower and 221 lb-ft of torque. Features like Double VANOS (BMW’s variable valve timing system) and an electronically controlled throttle contributed to its efficiency and responsiveness, making it a standout for enthusiasts and commuters alike.

Source: BMW

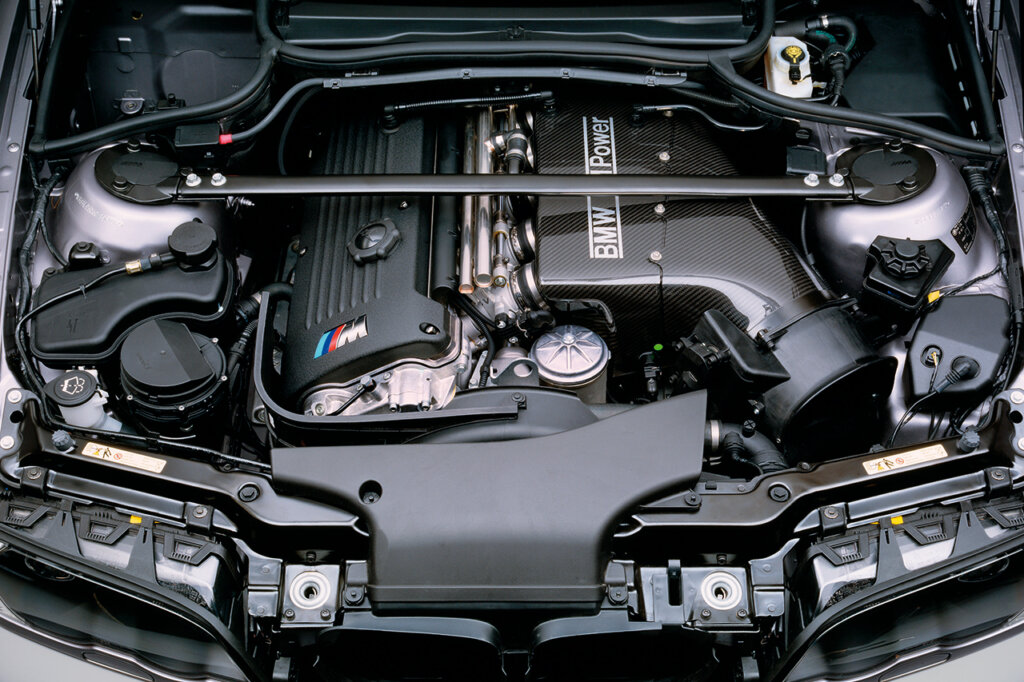

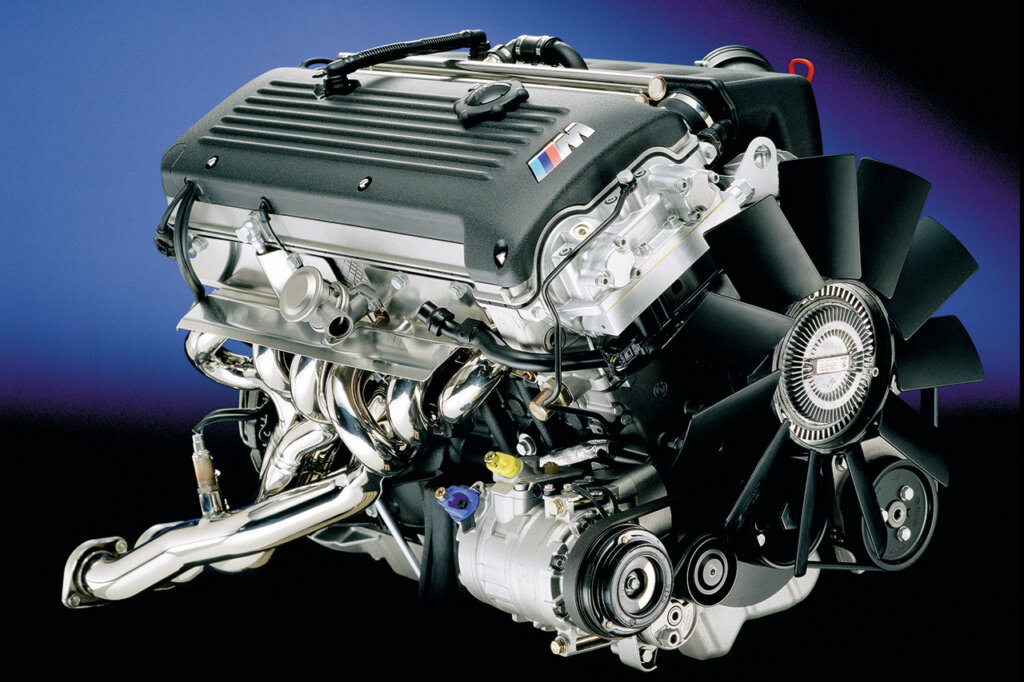

In contrast, the S54 engine, introduced in the high-performance E46 M3 and later the Z4 M models, was designed with motorsport in mind. Derived from the earlier S50 engine, the S54 boasted a cast iron block for increased strength and durability under extreme conditions. It featured individual throttle bodies, a high compression ratio of 11.5:1, and a forged crankshaft. These advanced components enabled the S54 to achieve 333 horsepower and 262 lb-ft of torque in standard trim, with the CSL variant pushing output even higher. Its redline of 8,000 RPM was a testament to its engineering pedigree, offering exhilarating performance on the road and track.

Source: Motofutura

The materials and design of these engines reflect BMW’s commitment to quality and performance. The aluminum block of the M54 provided weight savings, while the cast iron block of the S54 ensured durability under high stress. Both engines utilized six cylinders arranged in a straight line, a configuration that naturally minimizes vibration and maximizes efficiency. The inline-six’s harmonious balance and firing order contribute to the smooth, linear power delivery that BMW enthusiasts adore. This layout became a hallmark of BMW’s performance engineering, elevating models like the E46 M3 to legendary status.

The BMW M54 & S54 engines have become favorites among tuning enthusiasts. The M54’s robust design allows for modifications like forced induction, enabling power gains well beyond factory specifications. Meanwhile, the S54’s motorsport-derived components make it an ideal platform for track-focused builds, with upgrades often targeting its already impressive intake and exhaust systems. Both engines’ modularity and strong aftermarket support have ensured their continued relevance, even decades after production ceased.

BMW clearly knows power. (Shown E90 M3, E46 M3, E36 M3, E30 M3 & F82 M4)

Source: BMW

These engines paved the way for the N52, BMW’s first mass-produced engine with a magnesium-aluminum composite block. While the N52 incorporated advancements in weight reduction and efficiency, it owed much to the M54’s foundational design and the S54’s performance innovations. Together, BMWs M54 & S54 embody their dedication to engineering excellence, leaving a legacy celebrated by enthusiasts and serving as a benchmark for future inline-six engines. Their enduring appeal is a testament to their engineering brilliance and their ability to connect drivers with the pure essence of BMW performance.